How AI Powered Master Data Management(MDM) Transformed a Global Production Powerhouse

How a Global $5B Manufacturer Fixed Its Data Chaos in 90 Days

The Problem in Simple Terms

A leading North American manufacturer with $5 billion in annual revenue faced a major data challenge. Customer, supplier, product, and compliance information was fragmented across more than 95 ERPs and source systems, which includes SAP, Salesforce, JD Edwards, CRM Dynamics, SCALA, and homegrown ERPs. Each acquisition added new systems and data formats, resulting in data silos that didn’t communicate with each other.

Example of A Missed Opportunity

While there are countless cases of missed opportunities, one example stands out. A customer was recorded as ABC Corporation in one system and A.B.C. Corp in another. Because the records were never unified, the company failed to recognize that this client was already spending $3 million annually with the services division. When a regional account manager closed a $500,000 deal, the chance to bundle a $1 million-per-year maintenance contract was lost. The absence of a Golden Record meant fragmented visibility — and millions in revenue left on the table.

These fragmented and inconsistent data records created operational inefficiencies, compliance risks, and millions of dollars in lost revenue opportunities. Teams often discovered data issues too late to act without delays or inaccuracies. It was clear that a unified, scalable approach to Master Data Management was required.

Key Issues

⦿ Fragmented Customer Data: The same customer existed under multiple names (e.g., ABC Corporation vs A.B.C. Corp) across separate CRM and ERP systems, leading to missed cross-sell opportunities.

⦿ Supplier and Product Data Inconsistency: Over 1.8 million supplier and product entries were scattered across 95+ systems, causing duplicates and inaccuracies.

⦿ Compliance and Regulatory Risks: Compliance data (REACH, OSHA, SDS records) was misaligned across systems, creating reporting delays and potential regulatory exposure.

⦿ Inefficiencies in Operations: Manual data reconciliation, slow onboarding, and inconsistent reporting resulted in lost revenue and operational bottlenecks.

How 4DAlert MDM Solution Changed the Game

After implementing Master Data Management (MDM):

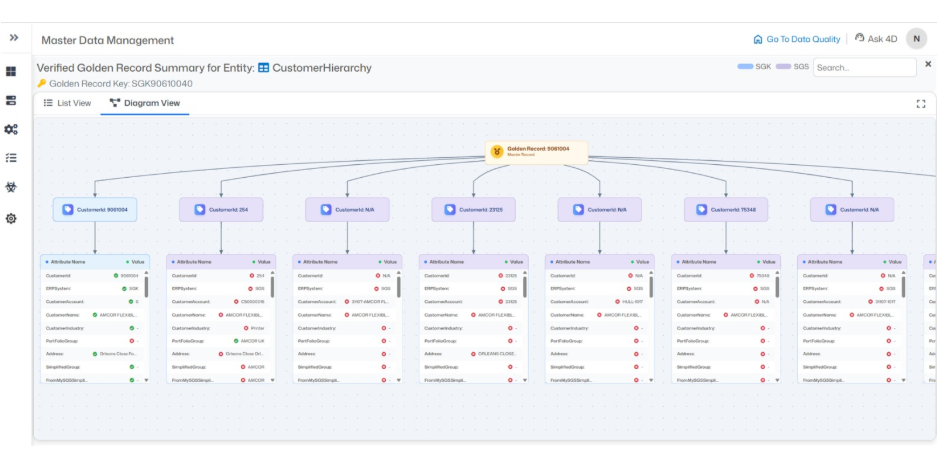

⦿ Customer records from CRM, ERP, and service systems were consolidated into a Golden Record.

⦿ Duplicate accounts like ABC Corporation vs A.B.C. Corp were merged.

⦿ Sales, marketing, and service teams gained a 360-degree view of every customer, including history, preferences, and relationships across business units.

The next time a similar customer came up for renewal, the sales team didn’t just pitch products—they offered a bundled package of parts, services, and warranties. This single view of the customer turned what used to be a $500K deal into a $2M strategic account.

The Impact

⦿ Cross-sell revenue grew 12% in the first year.

⦿ Sales cycle shortened by 18%, as account managers had complete customer context upfront.

⦿ Customers reported a better experience, no longer frustrated by inconsistent or duplicate communication from different departments.

This story shows how a simple data gap—two versions of the same customer—can cost millions, and how MDM turns lost opportunities into growth drivers.

The 4DAlert Solution Explained

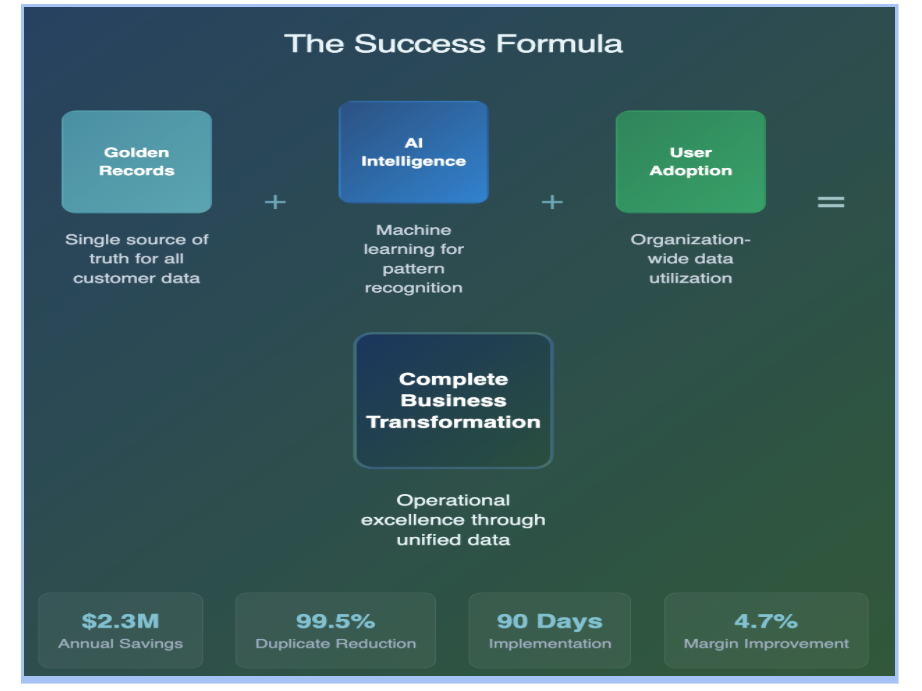

The manufacturer selected 4DAlert’s Master Data Management (MDM) platform for its AI-powered approach. Instead of patching each system individually, 4DAlert created Golden Records – single, trusted versions of each supplier, product, and regulatory entity that every system could reference.

TThe solution combined five powerful components:

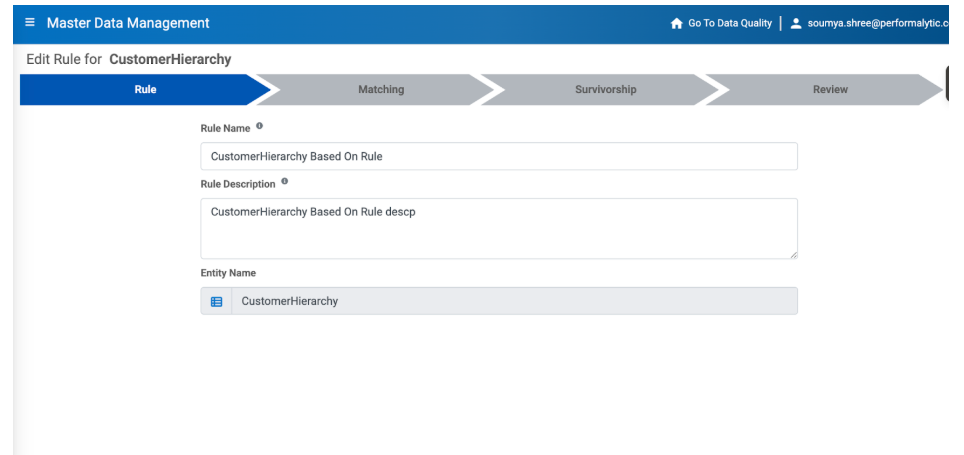

⦿ AI-Powered Matching Engine : Contextual and probabilistic matching to detect duplicate suppliers and conflicting product records.

⦿ Golden Record Creation: Survivorship logic that chose the most reliable product specifications, compliance attributes, and supplier details.

⦿ Real-Time Synchronization Hub: Updates in one system flowed instantly into SAP, Oracle, Snowflake, and LIMS.

⦿ Inbuilt Data Quality Management : Continuous validation and reconciliation rules to keep supplier, product, and compliance data accurate.

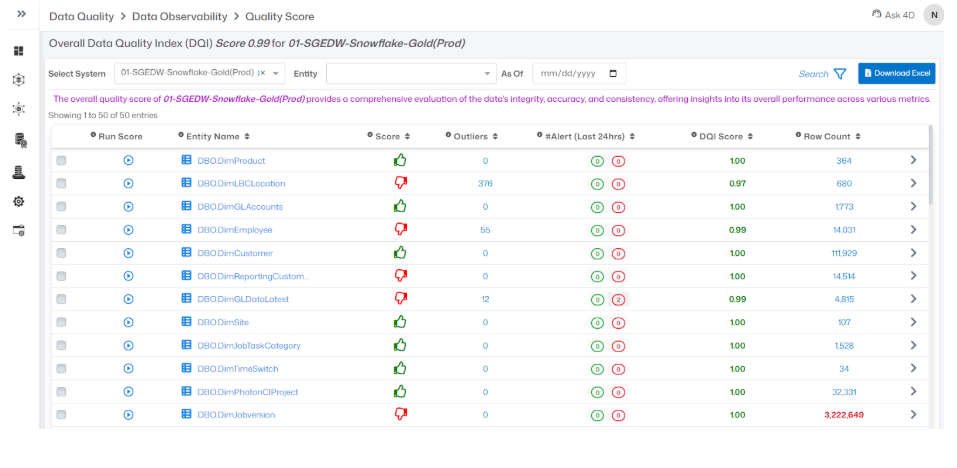

⦿ End-to-End Data Observability : Dashboards and anomaly alerts to detect errors before they disrupt supply chain or compliance reporting.

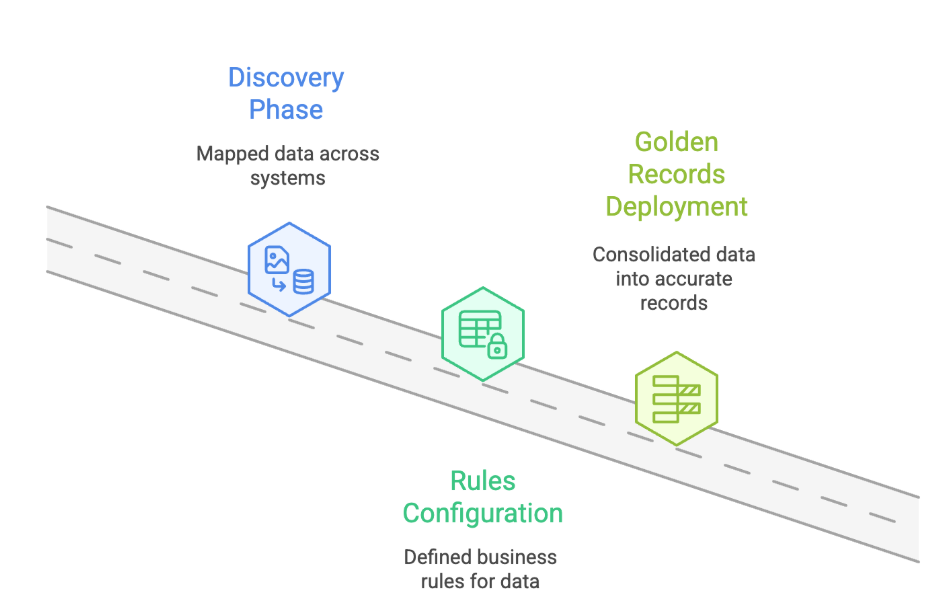

60-Day Implementation Journey

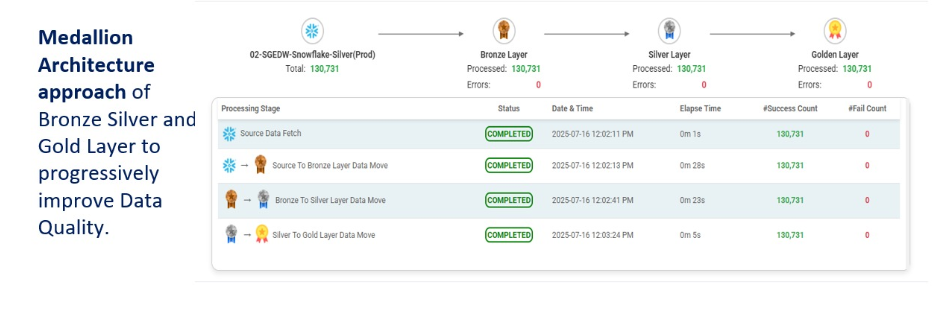

The transformation was completed in just 60 days through a structured process:

⦿ Week 1–2: Discovery Phase: Mapped supplier, product, and compliance data across 18 ERP, procurement, and LIMS systems. Focus areas: Customer(biggest issue), products (most complex), compliance records (most overlooked).

⦿ Week 3–4: Rules Configuration: Defined business rules, such as SDS data overrides procurement records and global product specifications take priority over regional versions.

⦿ Week 5-8 Golden Records Deployment : Final Golden Records consolidated supplier and product entries into a single, accurate set of records, eliminating duplicates and ensuring compliance data is aligned.

The Amazing Results

The company saw immediate efficiency gains and long-term business value:

Customer 360° Insights

⦿ Unified customer view eliminated fragmented records (e.g., ABC Corporation vs A.B.C. Corp).

⦿ Sales teams gained visibility into full client spend, uncovering hidden opportunities.

⦿ Result: A previously missed many contracts to the tune of $1M/year was captured, driving higher cross-sell and upsell revenue.

Supplier Data Excellence

⦿ Duplicate supplier records reduced by 98%, creating one accurate version of truth.

⦿ Supplier onboarding 40% faster (10 weeks → 6), with fewer errors.

⦿ Procurement accuracy improved by eliminating duplicate purchase orders.

⦿ Result: $2.5M annual savings in procurement efficiency and compliance reporting, plus $1.1M in new supplier discounts from consolidated contracts.

Product Data Excellence

⦿ Harmonized product records eliminated inconsistent SKUs and duplicate items.

⦿ Improved demand forecasting reduced safety stock requirements.

⦿ Result: $3M reduction in inventory overstock, freeing up working capital and improving cash flow.

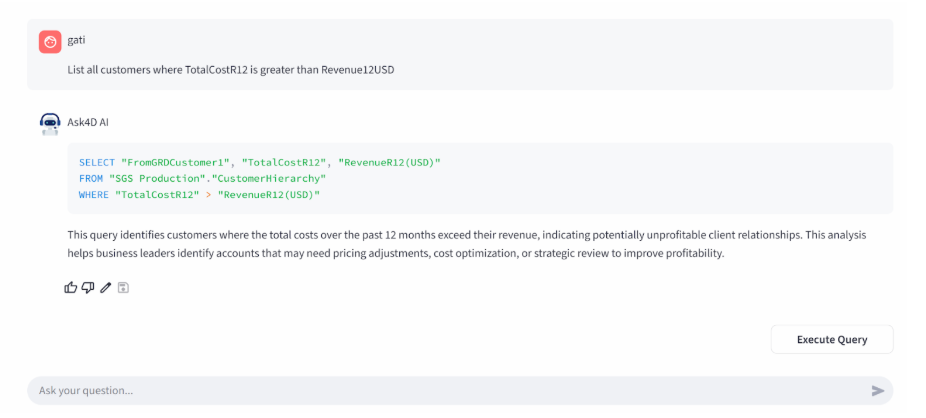

Ask4D – The GenAI-powered based Co-Pilot

4dAlert delivers Ask4D, a Generative AI-powered assistant designed to simplify and expedite interactions with Master Data Management (MDM) systems. By enabling users to query and interpret data through natural language, Ask4D has significantly enhanced MDM adoption within organizations.

While AI Powered Golden record creation process expedited the Match &Merge and Survivorship, 4DAlert’s LLM based assistant increased the adoption among the user community.

Real Examples in Action:

⦿ “Which suppliers are duplicated across SAP and Oracle, and what is the spend impact?”

⦿ “Show me products missing regulatory certificates due in the next 90 days.”

⦿ “List customers with incomplete tax IDs that could block invoicing.”

Key Benefits of Ask4D in MDM Adoption

1. Simplified Data Access: Ask4D democratizes data access by allowing users to retrieve insights without requiring technical expertise. This approach reduces the dependency on specialized skills and accelerates decision-making processes.

2. Enhanced Data Quality: Integrated with AI-powered Match & Merge capabilities, Ask4D helps eliminate duplicates and ensures data accuracy, leading to more reliable master records.

3. Accelerated Onboarding: The intuitive interface of Ask4D reduces onboarding and training time by nearly 50%, facilitating quicker adoption across teams.

4. Improved Time-to-Insight: By enabling users to obtain insights in real-time through natural language queries, Ask4D reduces the time-to-insight by nearly 75%, enhancing operational efficiency.

Conclusion

Ask4D exemplifies how integrating Generative AI into MDM systems can transform data management practices. Its user-friendly interface and advanced data processing capabilities make it a valuable tool for organizations aiming to enhance data accessibility and quality, thereby fostering greater adoption of MDM initiatives.

Unexpected Strategic Advantages

Beyond efficiency, the manufacturer unlocked new strategic benefits:

⦿ Supply Chain Optimization: Better supplier relationships through clean contract data

⦿ Product Consistency: Harmonized product master data reduced waste and formulation errors

⦿ Data-Driven Decisions: Unified data improved R&D, demand forecasting, and pricing strategies

⦿ Regulatory Compliance: Faster, more accurate REACH, OSHA, and EPA reporting

Key Lessons for Other Companies

The journey highlighted key lessons for modern Master Data Management (MDM).

Technology: AI-powered matching was vital for managing scale and complexity, outperforming traditional rule-based systems.

Strategy: Quick wins built confidence while full capabilities grew in parallel. Change management and training were just as crucial as the technology.

Impact: Focusing on business outcomes—new customer experiences, advanced analytics, and strategic capabilities—delivered measurable results.

Ready to Transform Your Data?

With AI-powered MDM, organizations can overcome fragmented data, duplicates, and conflicting reports to unlock real business value.

Signs You Need This Solution:

⦿ Multiple customer records for the same people

⦿ Different departments reporting different numbers for the same metrics

⦿ Manual processes for data validation and cleanup

⦿ Slow response times for business intelligence requests

⦿ Customer complaints about inconsistent experiences

What 4DAlert Offers:

⦿ Proven AI-powered Master Data Management platform

⦿ 90-day implementation timeline with measurable results

⦿ Immediate ROI through operational efficiency gains

⦿ Long-term strategic value through enhanced analytics capabilities

⦿ Technologies tested at enterprise scale with billions of records

Contact 4DAlert today to start your journey from data chaos to Golden Records success. The transformation is proven, the technology is ready, and the business results speak for themselves.